The apple industry is an iconic piece of Washington’s historic identity, and an integral part of the state economy. The industry has been defined traditionally by long-standing orchards, tended through the generations. Apple production comes with visions of red apples picked in autumn, on long ladders, filling wood bushel baskets, loaded in the back of a farm truck, and off to market. Today, however, this bucolic vision is supported behind the scenes and throughout distribution by high-tech systems that maximize product quality and increase efficiency of bringing the highest quality apples and products to consumer markets worldwide.

High Tech Origins for the Humble Apple

Washington’s soil, climate, and extensive irrigation system make it an ideal place to grow apples. Washington’s apple industry has grown to be the largest in the nation, leading 32 commercial apple growing states. In addition to the natural competitive advantages that Washington has, an extensive network of supporting activities is required to keep the industry leading the nation in apple production. Today, STEM jobs in crop production and support activities total more than 300 jobs in Washington; what was once a niche segment has grown into an essential component of apple farming. Life and physical scientists make up the largest portion of these jobs, almost 180, including foresters and soil and plant scientists.

STEM jobs alone do not tell the full story of how the apple industry is impacted by technology. Today, farm managers and supervisors rely on software to track farmworker productivity and capacity. Farm machinery maintenance workers leverage computer-aided diagnostics to make their work more efficient, and agricultural logistics experts utilize the latest logistics tracking software to ensure that fresh product arrives in a timely and efficient manner. Farmworkers and laborers use technology to find seasonal work and are increasingly expected to use technology on the job.

Research and Development

Hard science allows apple growers to manage risk in new ways, and biostatistics and genetics develop new apple varieties. While the traditional process of breeding apple varieties—breeding trees with desirable traits together until one yields the sought-after result—remains in place, researchers apply new technology to save time and effort throughout the breeding process. WSU tree fruit geneticists at the WSU Tree Fruit Breeding Program have identified markers in the apple genome that reflect different fruit qualities and plant disease resistance. Marker-assisted breeding helps breeders select which seedlings have the traits they are looking for long before they bear any fruit, saving significant time and effort. (WSU, 2015)

WSU’s Cosmic Crisp varietal, released after 15 years of traditional breeding, is a prime example of the importance of research and development for the apple industry. WSU’s newest variety, projected to be available to consumers by 2019, is expected to help Washington’s apple industry stay abreast of consumers' changing tastes in apples.

Workforce Development

The same institutions that engage in tree fruit research also train orchard managers, soil testing experts, and other workers essential to the state’s apple industry (which employs almost 28,000 people annually). Washington’s educational assets are valuable sources of STEM talent for the apple industry. Walla Walla and other community colleges, WSU, the Perry Institute of Technology and the University of Washington all have programs directly related to agriculture technology. Some of these programs include agricultural mechanization, agricultural engineering, botany, plant biology and agricultural and horticultural plant breeding.

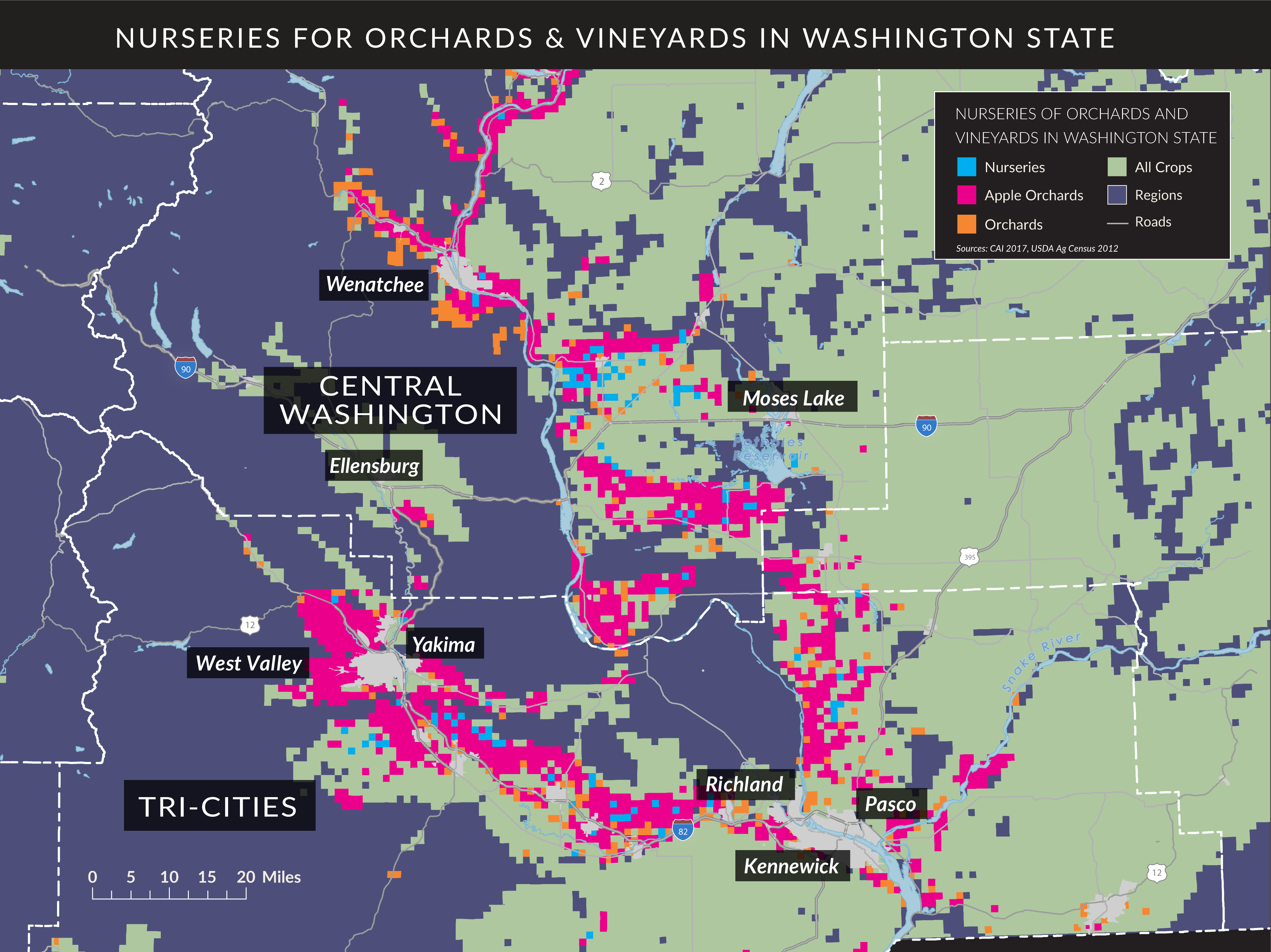

Nurseries

For an orchard manager, the apple growing process begins with rootstock, which nurseries grow for the first one to two years of the trees’ lives. Orchards rely on fruit tree nurseries and their own on-site nurseries. Pullman-based Phytelligence is implementing a new way to propagate apples. Instead of the traditional method of establishing fruiting trees for cuttings, which can take several years, the company initiates the growth of apple trees through tissue cultures in petri dishes where advanced software allows researchers to customize nutrients and analyze progress. This advanced technique cuts down propogation time significantly, and Phytelligence boasts a unique ability to produce 80,000 two-foot trees within seven months of receiving 500 plant tissue samples. The company was founded in 2011 by Dr. Amit Dhingra, then a genomicist at WSU, and his research team. (Good Fruit Grower, 2013; Phytelligence, 2017)

Burien, King County

Trees grow in soil...right? Washington State University start-up Phytelligence has figured out a way to grow trees - most commonly fruit trees - in a nutrient rich gel. This process was first created by Washington State University’s Professor Amit Dhingra in 2012 out of his Horticulture Genomics and Biotechnology Research laboratory, and now has 70 employees. The company has offices in Burien, Pullman and Portland, and grows up to 29 million plants each year. Primarily used during a tree’s early stages of growth, Phytelligence’s gel creates a controlled environment that helps cut down the number of viruses that might attack the young tree roots, and also helps maintain uniformity of the trees. Not only does this gel help create a more pest-free growing environment for trees, it helps farmers grow more plants more quickly. This sustainable technology supports the expedited growth of crops - from apples and cherries to almonds and hops, while decreasing water, pesticide, and fungicide use.

Learn more: Seattle Times Article , Phytelligence

Orchard Equipment

Orchards rely on equipment, much of which is common to other agricultural products and can be purchased from agricultural wholesalers. Some more specialized equipment is used in the apple industry, including spray applicators, shade cloth and netting, and trellising equipment. De Kleine Machine Company of Prosser, Washington with support from the Washington Tree Fruit Research Commission, WSU and Century Steep developed a model using elevation, wind and soil data to predict trellis load. This model is used to design trellises specific to individual orchards. Equipment wholesalers with specialized fruit tree equipment can be found across the state.

Equipment manufacturers increasingly incorporate technologies into their products to increase efficiency and cost savings for orchards and other agriculture producers. Nelson Irrigation in Walla Walla has developed a wireless irrigation control system for use in agriculture. The system gives users more precise control over irrigation cycle times compared to traditional hardwired systems, enabling farm operations to save water, energy, and chemical inputs while collecting detailed data on irrigation and water meter readings. (Nelson Irrigation)

Apple Orchards

Apple orchards are the center of the apple industry supply chain, where the fruit is grown and harvested. Apples are grown throughout Washington state, with concentrations in Central Washington .

Washington’s orchards are primarily small orchards, with more than 1,300 across the state with less than 15 acres. However, a few very large orchards make up the bulk of Washington apple production: the top 13 percent of orchards by size account for roughly 74 percent of the state’s bearing apple acreage.

Soil Testing and Tree Planting

New orchards require significant effort to make land ready for apple trees. Site preparation starts with soil testing, providing essential information on soil quality and depth. Yakima-based Agrimanagement takes soil testing one step further by integrating sampling data with GPS location information. The company integrates soil data into a layered GIS system and relates it to other on-farm information. Agrimanagement’s soil data and reports include suggestions for soil amendments based on the grower’s needs and the soil data.

Training Apple Trees

For the first several years after planting, young trees need to be trained. Some larger varieties will need either single pole systems or trellises to grow in the desired direction. Some orchards are implementing a high-density “fruiting wall” approach to trellising that results in trees that put less energy into trunk and branch development and more energy into growing apples. Fruiting wall trellising makes it easier for humans and robots alike to identify and pick ripe apples.

Companies like Automated Ag Systems of Moses Lake are helping orchard managers improve apple production and worker safety through the use of technology and mechanization. Orchards like Stemilt Ag Services in Wenatchee and Green Acre Farms near Harrah are using the Automated Ag System Bandit harvest assist platform to improve performance. (Automated Ag Systems, 2017; Capital Press, 2014)

Operations & Management

Orchards are using new technology and research to make their operations more efficient and cost effective. Orchard managers and consultants are turning to unmanned aerial vehicles (UAVs, or drones) to scout orchards, count trees, and assess tree stress. Trained experts interpret infrared images of orchard canopies to assess tree health—unhealthy foliage reflects away less UV light than healthy foliage. Drones can also identify water buildup due to leaks or poor drainage, giving managers a head start on implementing solutions. Today, Richland-based UpAngle Drone Services uses its drone fleet to inspect land, objects, and structures for the agriculture and mapping industries. (Fruit Growers News, 2015; UpAngle Drone Services, 2017)

For Oneonta Starr Ranch Growers in Wenatchee, food safety and quality control begins in the orchard. Field experts use penetrometers to test the firmness of apples while they are still on the tree and refractometers to test the sugar content of apples. Armed with this information, orchard managers can pick the optimal time to pick their fruit, and determine fruit quality far in advance of picking.

Apple Harvest

When apples are ready for harvest, orchards hire a large number of seasonal workers. The industry is reliant on access to a limited pool of skilled seasonal workers, including field laborer, packers, and equipment operators. Websites that connect laborers to farms have transformed the way seasonal labor operates. For example, pickingjobs.com connects laborers to farms, giving orchard owners access to a larger talent pool while simultaneously offering access to more information on potential jobs to laborers.

Although most picking is still done by hand, automated harvesting is increasingly being used. WSU researchers are working on an apple-picking robot that uses computer vision to identify apples, navigate leaves and branches to get to apples, and grasp apples gently enough to remove them from the tree without bruising them. The WSU research team used pressure sensor gloves to measure the force applied by human apple pickers to determine the right pressure for the robotic arm.

Storage

After harvest, apples are tested for sugar and starch content to estimate when they will be at peak flavor. Apples with the highest sugar content will be ideal for consumption soonest, and are immediately placed in temperature- and oxygen-controlled environments that prevent apple decomposition, ensuring they arrive to their final markets fresh. Apples with lower sugar content are sent to controlled-atmosphere environments that slow their maturation. This high-tech solution allows farm-fresh apples to be sold throughout the year. Orchard automation may help orchard owners address a perennial problem: seasonal labor shortages.

The controlled warehousing environments that allow apples to be sold throughout the year are part of the larger transportation and warehousing industry in Washington. The high-tech solutions that are increasingly utilized by these industries rely on a wide range of tech jobs. The transportation and warehousing industry in Washington has more than 2,400 STEM jobs, of which more than 930 are in computer and software occupations, such as software developers and computer systems analysts.

Often, large orchards have their own cold storage facilities. Selah-based Matson Fruit installed an automated storage retrieval system in its warehouse. This robotic system automatically places and retrieves loads based on user input and a database of information gathered about customer preferences and needs. With this information programmed into the system, employees don’t need to remember customer pallet type or fruit size preferences. (Growing Produce, 2014)

Apples Sales

Sorting & Packing

When apples are taken out of cold storage they are graded and sorted by hand or by a machine. Depending on apple size and the presence of any defects, some apples are destined for fresh-to-market consumption and are packed immediately after sorting, while others will be processed and packaged. In 2015, almost 82 percent of apples produced in Washington were sold in fresh markets, while the remaining 18 percent went on to processing.

Food Processing plays an important role in the supply chain for apples and other Washington grown agriculture products. Overall, the food processing industry is made up of almost 37,140 jobs, which include a significant number of STEM jobs. This industry relies on more than 550 STEM jobs, including more than 200 engineers, such as industrial and mechanical engineers.

Technologies are revolutionizing the packing and sorting process for Washington companies. Washington Fruit & Produce, a 100-year-old apple, pear, and cherry grower based in Yakima, completed new packing plants in Yakima in 2015. The new plants use optical sorters that assess apples for external defects and internal bruising. While the company still employs the same number of workers, fewer workers are involved in manual defect sorting, increasing the operation’s efficiency. The company also uses a new supply chain system that allows it to trace fruit down to the box level, ensuring that the correct product is shipped to each customer. Advanced traceability programs also help public health officials trace and prevent potential safety concerns.

WSU researchers are investigating ultraviolet C (UV-C) light as a way to ensure food safety on fruit packing lines. The team found that most E. coli and listeria microbes were killed within the first minute of exposure to UV-C light. The team also reported that the UV-C light had no or only minimal visual effect on the treated fruit. UV-C light may be an alternative to chemical treatments for organic fruit growers and packers. (Good Fruit Grower, 2015)

Columbia Marketing International (CMI) recently opened a new packing facility based on the latest available technology. In 2012, just after opening the new apple packing line, CMI reported that its use of advanced sorting technology and efficient processing strategies increased apple through-put by roughly 30 percent.

Transportation

Columbia Valley Fruit in Yakima uses an automated system to scan all packaged fruit before it enters the truck, ensuring accurate shipments which result in happy customers and better return for the company.

Dovex Services transports Washington apples across the globe. The company leverages transportation and logistics software to export the state’s apples to Argentina, Brazil, Peru, Chile, China, Mexico, Italy, Spain, and South Africa. Modern transportation companies use complex shipment tracking and management programs to ensure that customers receive the correct deliveries at the correct time.

Seattle-based start-up Convoy has created an app to connect shippers to the right truck. Convoy allows shippers to enter their shipment details, get real-time pricing, track their shipment through GPS and receive analyzed data to help optimize transportation. For carriers, Convoy provides flexibility and provides payment quicker than traditional shipping.

Final Markets

Washington’s apple industry is export-oriented, both to other markets in the nation and foreign markets. Innovations in packaging, fruit coatings, bioengineering (controlled ripening), and other techniques reducing deterioration have helped shippers extend the reach of apples. In 2015, Washington state sent approximately one-third of its apple production abroad, $796.7 million out of $2.4 billion. The remaining two thirds of the state’s apples are sold domestically to grocery stores, farmer’s markets, restaurants, and food services.

Final markets in Washington include grocery and related stores as well as restaurants. These final markets rely on technology to reach their customers. The wholesale, retail and restaurant industries in Washington that sell Washington apples and other food products rely on almost 460 STEM jobs. Apples must be transported at the same temperature they were at in the cold storage facility so the trucks and railcars that convey apples need to make use of the latest technology to ensure timely, fresh delivery.

Many apple products are intermediate inputs into other goods, like apple puree used in baby food and dehydrated apples used in prepackaged oatmeal. These products are both sold domestically and abroad, with final products reaching consumers around the world. To achieve natural preservation of its apple products, TreeTop Inc., uses "Hurdle Technology" to prevent its products from becoming stale, oxidizing, spoiling or degrading if on the shelf for an extended length of time. According to TreeTop's Kevin Holland, Ph.D. "Shelf life can be extended by various hurdles, including pH, water activity, processing or storage temperature, and preservatives." TreeTop, an apple producer with two plants in Selah, has been able to use this "Hurdle Technology" on its apple products to create a natural preservative, eliminating the need for artificial preservatives. This technology has been instrumental to TreeTop's continued growth.

Wrap-up

The story of Washington apples is a story of Washington tech: the states apple growers, processors, research institutions and transportation experts have implemented tech solutions across the supply chain to combat problems as old as the industry itself. The natural ripening process used to dictate the availability and quality of fruit, but now apple growers can store their fruit in high-tech climate-controlled containers, allowing fresh fruit to be sold for more than just harvest season. Today’s complex apple supply chain is managed by advanced logistics software that improves efficiency and ensures that the right product goes to the right consumer. Washington’s apple industry and Washington State University are doing research and development that promises to offer tree fruit and other agriculture improvements to productivity, efficiency and safety.